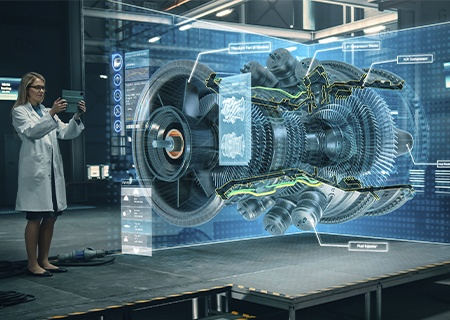

The use of digital twin technology within the prognosis course of permits healthcare professionals to simulate different eventualities and identify potential points without disrupting the affected person’s actual care. As a outcome, it could possibly help to improve the accuracy of prognosis and cut back the number of unnecessary tests and procedures. Engineers can take a look at quite a few designs and choose the most performing ones with out creating a single bodily prototype. The manufacturing course of cloud team may be optimized, reducing downtime and improving production price.

How Did The Idea Of Digital Twins Emerge?

Digital twins in healthcare include anything from affected person how does digital twin work circulate to resource management. Hospitals are able to pinpoint inefficiencies and put efficiency-boosting plans into motion by modeling numerous situations. For instance, to ensure that sufferers get treatment on time, digital twins can enhance the planning of operations and the distribution of beds. Digital twins in the energy sector allow companies to build accurate virtual representations of their power vegetation and other energy-generating assets. Businesses could ensure that these belongings run as effectively as possible by optimizing their performance via simulation of varied eventualities.

Ibm Maximo Asset Monitor – Best For Asset Health Insights

I selected this due to its emphasis on scalability with cloud integration, making it the prime alternative for organizations seeking to broaden without compromising on the quality or velocity of information interpretation. Cintoo Cloud stands as a formidable tool in the digital twin area, particularly designed to remodel laser scan knowledge into actionable 3D mesh. Its prowess in detailed point cloud integration makes it a go-to resolution for professionals who want intricate and precise data visualizations. We’re proper initially of this transition into reality, a lot as AI grew to become viable and created an explosion of potentialities,” stated NVIDIA’s Lebaredian. And all those in it is going to be in a place to entry the NVIDIA Omniverse platform for AI, human and robot interactions, and infinite simulations, driving a wild experience of advances from digital twins. Networking is an space where digital twins are reducing downtime for information centers.

Why Aren’t More Businesses Benefiting From Simulation-based Digital Twin Software?

This software platform is designed to work with Predix, GE’s software platform for the Industrial Internet, offering users with a broader spectrum of capabilities. The platform’s integrations lengthen to varied different instruments and providers, maximizing its potential in diverse operational situations. Digital twin technology allows you to create higher-quality merchandise, buildings, and even complete cities.

Digital Twin Example- Digital Singapore Platform

Real-time occupancy information additionally permits property managers to respond shortly to changing tenant wants and preferences. For example, if a particular constructing space is persistently underutilized, the property supervisor can use this data to repurpose the house. Two highly effective functions that leverage digital twins to elevate tenant experience are Utilize and Flowscape. The quite a few members in a supply chain have to be prepared to share data from their own production processes to ensure that the data in a digital twin is full. Digital twins typically begin life in CAD software however get extra use in PLM, the place they’re used in post-sale providers, such as performance monitoring and gear upkeep. Numerous CAD and PLM software vendors have one-to-one integrations, however it isn’t at all times sufficient and smaller distributors may need no built-in integration.

Which Software Program Is Used To Build Digital Twins?

It consists of as-is, to-be, and real-time views of the community and allows all departments to contribute and eat information that help ship better outcomes. According to a McKinsey report, the worldwide economic influence of Digital Twins is forecasted to succeed in $1.three trillion to $2.0 trillion yearly by 2025, signifying their transformative potential throughout diverse sectors. This service provides real-time monitoring of the store flooring, enabling seamless communication among manufacturing techniques and interplay between methods and human operators. This collaboration enhances production effectivity and elevates the decision-making course of, optimizing overall manufacturing efficiency.

Digital Twin Influence At A Fraction Of The Time

- Process twins, the macro stage of magnification, reveal how methods work collectively to create a complete production facility.

- When this simulation software program is combined with sensors and data, it results in a sophisticated structural digital twin capable of holistic, high-fidelity 3D simulations at the pace of thought.

- These instruments are seamlessly linked to the virtual twin, allowing for continuous design refinement based on knowledge and simulation results.

- Examples embody sensor knowledge like temperature or moisture, RFID information like worker foot visitors and badge entry, and geolocation monitoring of automobiles or provides.

For instance, power producers can reduce machine degradation while improving efficiency by real-time altering components like temperature and stress. The way ahead for digital twins is nearly limitless as a result of growing quantities of cognitive power are continuously being dedicated to their use. So, digital twins are continuously learning new skills and capabilities, which means they’ll proceed to generate the insights wanted to make merchandise better and processes more environment friendly. Better R&DThe use of digital twins enables more effective analysis and design of merchandise, with an abundance of knowledge created about doubtless efficiency outcomes.

What Precisely Is Digital Twin Software?

These tech-driven insights might help firms make data-led selections and keep forward of the competitors. The way ahead for digital twins appears promising, with the potential to revolutionize the way in which we design, build, and maintain bodily property and methods. A digital twin is a virtual/ digital duplicate of bodily entities similar to devices, individuals, processes, or methods that assist companies make model-driven selections. Digital twins are altering the way work is done in several industries with various business applications. Knowing those applications can help businesses implement digital twins into their processes. Therefore we examined digital twin functions in manufacturing, healthcare, supply chain and retail.

Digital twins offer a way to standardize knowledge that is currently held in siloes by disparate systems and options. Rather than merely using AI computer vision to detect objects in a camera view, the digital twin opens contextualized scene information to any system or solution at the user’s behest. Another characteristic that could be observed, is the truth that digital twin applied sciences depart digital traces.

The Port of Rotterdam is utilizing IBM digital twin know-how to remodel itself from the largest to the neatest. Process twins, the macro level of magnification, reveal how techniques work together to create an entire manufacturing facility. Are those systems all synchronized to function at peak efficiency, or will delays in a single system have an effect on others? Process twins might help determine the exact timing schemes that in the end influence overall effectiveness. Asset twins let you research the interplay of these elements, creating a wealth of efficiency data that can be processed after which became actionable insights. Examples include sensor data like temperature or moisture, RFID data like employee foot visitors and badge entry, and geolocation tracking of automobiles or supplies.

Follow the link to read how digital twins can enhance employee training within the automotive industry. Digital twins also can pave the means in which for a more sustainable way of how we construct buildings. You can read extra about how digital twins may help with sustainable construction.