Complex Integration – Synchronizing completely different systems, from design to production to stock, requires seamless integration, which could be intricate. Implementing Computers Integrated Manufacturing can result in the potential loss of jobs within a corporation. Job displacement is a major concern in terms of the adoption of this manufacturing approach. As duties that were previously carried out by humans are automated, there’s a risk of unemployment for those whose roles become redundant. This has financial implications, as job loss can lead to monetary instability for individuals and their families. Intelligent models can handle billing, scheduling, logistics route planning and extra to reduce errors and promote larger efficiency.

GE’s CIM system includes advanced robotics and automation, enabling the company to cut back labor prices and improve efficiency. The CIM system additionally includes real-time monitoring and knowledge analytics, allowing GE to optimize production processes and enhance quality. Integrating the CIM applied sciences and options with the present methods and processes. CIM is not a standalone system, but a system that interacts and communicates with other systems and processes, such as the product design, the stock management, the standard control, or the customer support. Therefore, it is crucial to make certain that the CIM applied sciences and solutions are built-in with the existing techniques and processes, and that there are no conflicts or redundancies.

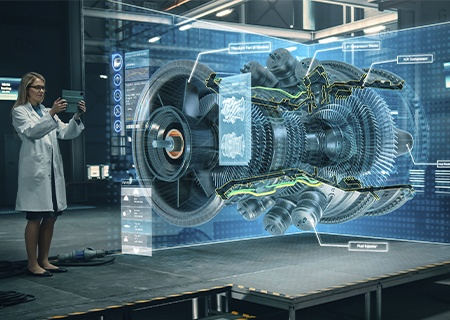

Adopting microservices architecture enabled adding new Artificial Intelligence-related services. For occasion, we applied options for anomaly detection, route recommendations, supply prediction, and object detection in logistics. FM Alarms (Industrial Alarm Notification and Processing System) can detect irregular behavior of kit and notify responsible staff members by way of mobile gadgets. It identifies affected belongings and offers the user with various data wanted for reactive maintenance scenarios in addition to tools control functions from cell.

We suggest that central administration of computer-integrated manufacturing methods is essential. There’s no query that digital operations are remodeling manufacturing. A vary of improvements that fall under the Industrial Internet of Things (IIoT) or Industry 4.0 umbrella all level in path of more computer-integrated manufacturing operations or the ‘connected enterprise’. With a lot driving on its performance, it’s baffling that many manufacturing corporations fail to put money into sufficient protection for what’s undoubtedly a capital asset.

If you should validate the profitability of your small business, you’ll find a way to undertake a Discovery Phase. Based on calculations for different eventualities, you can understand the advantages of implementing laptop integrated manufacturing. The Product Discovery part offers all the deliverables required to kick off the implementation phase efficiently whereas addressing risks and optimizing prices. Computer integrated manufacturing is about a extra innovative strategy to production, supply chain, inventory and warehouse administration, and so on. Accurate, real-time data from a quantity of factors throughout the production line can reveal enchancment areas. For example, say machine speed is increased from 5500 to 6000 items an hour.

In this section, we are going to explore the different levels of CIM integration and some examples of CIM applications in numerous industries. On one hand, computer systems integrated manufacturing can considerably enhance productiveness levels, streamline production processes, and improve accuracy and precision. Effective SCM requires collaboration and coordination between all of the stakeholders in the provide chain. It involves the sharing of knowledge and the use of know-how to make certain that all parties have access to the knowledge they want to make knowledgeable selections. This collaboration and coordination help to minimize back lead instances, reduce inventory costs, improve product quality, and increase buyer satisfaction.

Machine Studying

However, the system is recording higher waste output than when the machine was working at 5500. Despite apparently improving effectivity, the revenue margin is greater if the machine runs slower. Such insights can only be gleaned from correlating multiple data time limits. Ultimately, the goal is to attain most efficiency, closing those AI Software Development gaps that hinder productiveness and result in the bottom-line taking successful. Additionally, CIM plays a key role in gathering relevant, real-time knowledge from the manufacturing flooring. For occasion, to optimize efficiency, CIM can monitor the operational performance of important tools.

- One of the first challenges of implementing CIM in SCM is the numerous upfront investment required to implement and keep a CIM system.

- When there’s a certain number of faulty gadgets, the system can inform the manager or even halt the production for further inspection to be carried out.

- So, we found a top-notch CV specialist to run the pc imaginative and prescient workstream.

- The choice criteria should embody factors such as cost, compatibility, scalability, reliability, usability, and security.

- There’s no question that digital operations are remodeling manufacturing.

Additionally, the management of large amounts of knowledge in a computer-integrated manufacturing system can be challenging. Companies must put money into robust knowledge management systems and make certain that their workforce is educated to effectively utilize these techniques. This can have workforce implications, as staff may need to accumulate new skills or adapt to changing roles throughout the manufacturing course of. With automated methods, corporations can streamline their operations, ensuring that sources are allocated efficiently, leading to improved productivity and total performance. With computers built-in manufacturing, you can obtain cost-effective operations by harnessing the power of automation and optimizing resource allocation.

Understanding Computer Integrated Manufacturing (cim) Meaning

With the assistance of commercial IoT, 3D printing, and robotics itself, you’ll find a way to enhance the quality and consistency of the manufacturing process, in addition to the final product. Also, IoT permits real-life situation monitoring of your machines and their predictive maintenance. In straightforward terms, CIM is the technique of using computers to manage an entire production course of. It’s commonly used by factories to automate features such as analysis, cost accounting, design, distribution, inventory control, planning and buying.

Toyota’s CIM system includes real-time monitoring and knowledge analytics, allowing the corporate to optimize production processes and respond rapidly to modifications in demand. One important advantage is the ability to extend manufacturing effectivity. By automating production processes, CIM reduces the necessity for guide labour, which reduces production costs while growing productiveness. The automation of manufacturing processes additionally reduces the prevalence of errors and will increase product quality.

Pc Built-in Manufacturing Made Easy: Finest Practices And Use Circumstances

Computer Integrated Manufacturing (CIM) is designed to streamline the manufacturing course of by integrating numerous manufacturing processes right into a single, unified system. CIM enables producers to automate and optimize numerous features of the production course of, from design and engineering to production and high quality management. With CIM, producers can reduce lead instances, improve product quality, and enhance efficiency by automating repetitive tasks and eliminating handbook processes. CIM also enables producers to enhance communication and collaboration between different departments, enabling them to work more effectively collectively to optimize production processes.

CIM has many advantages for producers, similar to decreasing prices, improving high quality, increasing productiveness, enhancing flexibility, and enabling innovation. CIM is not a one-time project, but a continuous process that requires constant monitoring and analysis. The results must be in contrast with the baseline and the targets, and any deviations or discrepancies ought to be recognized and analyzed. The suggestions and classes learned from the monitoring and analysis should be used to enhance and optimize the CIM system, and to determine and implement new opportunities and improvements.

Pc Built-in Manufacturing: Tips On How To Automate And Streamline Your Manufacturing Course Of With Computer Systems

You could face high preliminary costs when implementing Computers Integrated Manufacturing. The preliminary investment required to implement this expertise may be substantial. This contains the price of buying and installing the mandatory hardware and software program, in addition to coaching workers to use the model new system effectively.

They wanted the answer with excessive requirements of safety, reliability, scalability, and extensibility. What are the necessary thing options that may help you expertise the benefits of computer integrated manufacturing? In this case, CV can analyze new photographs and compare them to an already current dataset to find anomalies and prevent doubtlessly harmful situations on manufacturing lines and manufacturing websites. What’s more, robotic options guarantee greater productiveness that maximizes throughput and minimizes human error. But producers can be reactive rather than preventative in relation to quality management. This is particularly true when quality reviews are solely out there the following day, or if the source of product defects can’t be pinpointed alongside the road.

Almost three in four workers lack the digital abilities essential to succeed in future tech-driven workplaces. That lack of talent and expertise can make it tough to implement Industry four.zero technologies successfully. AI, robotics and the IoT are all rising across manufacturing in their very own right. CIM brings them collectively and employs them to a greater extent, so it additionally combines and elevates their benefits. Also, we contributed to the event of the Fluke information platform — an IoT software platform supporting a collection of apps.

The Four Major Elements Of Cim Techniques And The Way They Work Collectively

CIM additionally provides real-time monitoring and management, enabling manufacturers to respond rapidly to changes in buyer demand or production points. The integration of CIM into the supply chain management process helps to ensure that products are produced and delivered effectively and effectively, resulting in increased customer satisfaction and loyalty. However, CIM also comes with some challenges and dangers, such as excessive prices, dependency, vulnerability, and moral and social points, which require cautious consideration and management.

In different words, not only will you see how you can scale back waste, but you can also anticipate potential problems and malfunctions before they appear. Contrary to the notion that CIM is suitable just for large-scale manufacturing, small companies can even reap the advantages of CIM. Small businesses can enhance effectivity and achieve cost reductions by deploying scaled-down versions tailor-made to their wants.

To mitigate these challenges, retraining packages can be implemented to assist affected staff acquire new expertise and transition to different roles throughout the organization or in other industries. We will discover a few of the major disadvantages of pc integrated manufacturing. It will take a quantity of years of spread-out adoption and tweaking to use Industry four.0 applied sciences across the whole workspace. This slower methodology could also be much less thrilling but is essential to managing costs and minimizing the harm from mistakes. Ideally, digitization — even on CMI’s scale — will help staff accomplish extra, not replace them.

The Key Components For Profitable Cim Adoption And Administration

In one case, a serious supermarket chain consolidated its forecasting, scheduling and traceability information throughout its meat processing operations. The answer involved a customized pull model that managed raw supplies according to store demands. The grocery store chain saved $50 per pallet and increased product shelf life by 1.5 days – all thanks to an integrative method that used obtainable data to raised track merchandise from farm to client. One is an essential software for finding one of the simplest ways to design the desired part, while the other mechanically feeds the answer to the best little bit of hardware that creates it. When used properly, these two strategies can deliver hundreds of items with precision and a low rate of manufacturing errors. They have reduced the variety of human sources initially used for this function and have automated the method in new and unimaginable ways.